T700 High Speed Drilling and Tapping Machining

Drilling and Tapping Machining Feature:

- Structural Design for High-Rigidity and High Dynamic Performance

- Fully Enclosed Protection with Oil Mist Collector

- Spindle Center Air Blast and Spindle Air Curtain Protection

- High-speed, high-precision performance control system.

share:

High Speed

High Spindle Speed: The spindle speed reaches up to 12,000/20,000 rpm, making it ideal for efficient drilling and tapping operations.

Rapid Traverse Rates: Fast axial movement speeds enhance processing efficiency by reducing non-cutting time.

High Precision

High Positioning Accuracy: Precision ball screws and linear guideway systems ensure high machining accuracy.

Repeatable Positioning Accuracy: Consistent accuracy is maintained when machining the same part multiple times, ensuring uniform quality.

Highly Automated System

Automatic Tool Changer (ATC): Equipped with an automatic tool-changing system, allowing for quick tool changes and improved machining efficiency.

Multi-Station Machining: Capable of performing various operations such as drilling, tapping, and milling, completing multiple processes in a single setup.

Great Stability

Rigid Structural Design: The robust design of the machine tool structure can withstand substantial cutting forces, ensuring stability and precision in machining.

Great Vibration Damping: Utilizes high-quality damping materials and designs to minimize vibration during machining, improving surface quality.

| Item | Unit | Parameter | |

|---|---|---|---|

| Travel | X travel | mm | 700 |

| Y travel | mm | 400 | |

| Z travel | mm | 330 | |

| Spindle center to column surface | mm | 150-480 | |

| Table | Table size | mm | 800×400 |

| Table load | kg | 300 | |

| T-slot | 3×14×125 | ||

| Spindle | Spindle taper | — | BT30 |

| Spindle speed | rpm | 12000 RPM ( optional 20000) | |

| Taper models | — | BT30-110/BT30-90 | |

| Tool Magazine | Tool Magazine type | Arm-type tool magazine | |

| Tool Magazine capacity | T | 26 | |

| Tool models | MAS403/45°-BT30 | ||

| Max. tool diameter(Adjacent vacant) | mm | φ60(φ80 adjacent empty) | |

| Max. tool length | mm | 2500 | |

| Max. tool weight | kg | 3( single),10( full load) | |

| Feed Speed | X/Y/Z rapid feed | m/ min | 48/48/48 |

| X/Y/Z cutting feed | m/ min | 12 | |

| Motor | Spindle servo motor model | check with configuration sheet | |

| Spindle power | kw | 3.7/5.5 | |

| Spindle torque | Nm | 18/27 | |

| X/Y/Z servo motor model | Check with configuration sheet | ||

| X/Y/Z servo motor power | kw | X, Y, Z: 2.5, 2.5, 2.7 | |

| X/Y/Z servo torque | Nm | 8/8/12 | |

| Ballscrew | Ballscrew diameter/ pitch | mm | XY:φ28/16 Z:φ32/16 |

| Liner Guide | Linear guide width/rails/blocks | mm | X:30/2/4; Y:30/2/4; Z:35/2/4 |

| Accuracy | Positioning accuracy | mm | X, Y, Z: ±0.008 |

| Repeated positioning accuracy | mm | X, Y, Z: ±0.005 | |

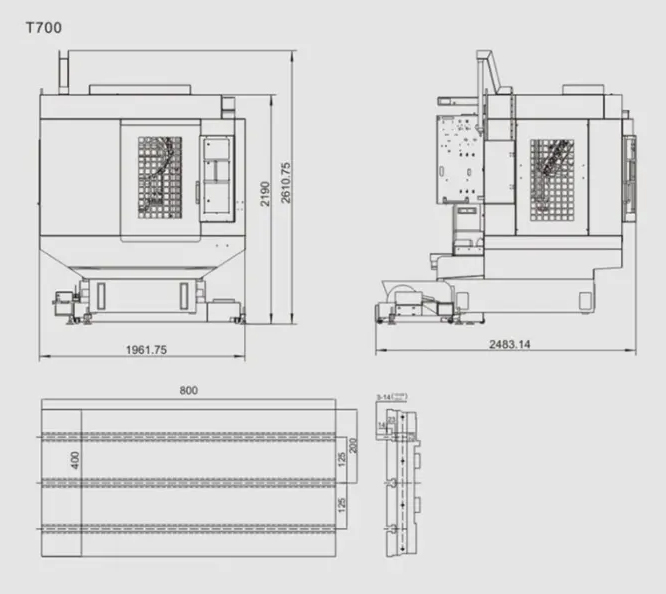

| Dimensions | Machine size(L*W*H) | mm | 1960×2500×2200 (including water tank) |

| Machine weight( Net) | kg | 3500 | |

| Power requirement | kw | ~16 |

| List Of Main Parts | |||||

|---|---|---|---|---|---|

| No. | Item | Brand | Quantity(set) | Brand Origin | Remarks |

| 1 | CNC Control System | FANUC | 1 | Japan | 0I-MF(Advanced package) |

| 2 | Main Servo Unit | FANUC | 1 | Japan | 3.7KW( Bil 3/12000-B) |

| 3 | Feed Servo Unit | FANUC | 3 | Japan | XY-Ais8/4000 |

| Z-Ais12/4000B | |||||

| 4 | Spindle | RIYE | 1 | China | |

| DEJO | China | ||||

| 5 | Ball Screw | PMI/HIWIN | 3 | Taiwan | |

| 6 | Ball Screw Bearing | SKF/NSK/NACHI | 6 | Japan | |

| 7 | Linear Guide | PMI/HIWIN | 3 | Taiwan | |

| 8 | Lubrication System | HEGU | 1 | Taiwan | |

| 9 | Hydraulic System | 1 | China | ||

| 10 | Coupler | 3 | Japan | ||

| 11 | Main Electrical Components | 1 | |||

| 12 | Boosting Cylinder | LEVER TYPE | 1 | China | |

| 13 | Tool Magazine | DEJIE | 1 | China | 26T Clip Arm Type |

| 14 | Pneumatic Components | SMC | 1 | Taiwan | |

| Optional Configurations | |

|---|---|

| No. | Item |

| 1 | Mitsubishi System/FANUC System/Siemens Cnc System/SYNTEC System |

| 2 | Heightened 150mm |

| 3 | Oil Cooler Device |

| 4 | Tool Setting Instrument |

| 5 | Water Gun |

| 6 | Fourth Axis Rotary Table |

| 7 | Oil-Water Separator |

| 8 | 20000rpm Direct-Connected Spindle |

| 9 | Automatic Door |

| 10 | Oil Mist Collector |

| 11 | Central Water Outlet |