T600 Durable Center Drilling for Efficient Metalworking Projects

Milling and Drilling Center Feature:

- Structural Design for High-Rigidity and High Dynamic Performance

- Fully Enclosed Protection with Oil Mist Collector

- Spindle Center Air Blast and Spindle Air Curtain Protection

- High-speed, high-precision performance control system.

share:

High Speed

High Spindle Speed: The spindle speed reaches up to 12,000/20,000 rpm, making it ideal for efficient drilling and tapping operations.

Rapid Traverse Rates: Fast axial movement speeds enhance processing efficiency by reducing non-cutting time.

High Precision

High Positioning Accuracy: Precision ball screws and linear guideway systems ensure high machining accuracy.

Repeatable Positioning Accuracy: Consistent accuracy is maintained when machining the same part multiple times, ensuring uniform quality.

Highly Automated System

Automatic Tool Changer (ATC): Equipped with an automatic tool-changing system, allowing for quick tool changes and improved machining efficiency.

Multi-Station Machining: Capable of performing various operations such as drilling, tapping, and milling, completing multiple processes in a single setup.

Great Stability

Rigid Structural Design: The robust design of the machine tool structure can withstand substantial cutting forces, ensuring stability and precision in machining.

Great Vibration Damping: Utilizes high-quality damping materials and designs to minimize vibration during machining, improving surface quality.

| ITEM | UNIT | PARAMETER | |

|---|---|---|---|

| Spindle | Spindle servo motor(continuous/30minutes) | kw | 82 |

| Maximum spindle speed(direct connection) | rpm | 12000/20000 | |

| Spindle specifications | BT30100/110/ | ||

| BT40-120 | |||

| The Scope Of Work | X-axistravel | mm | 600 |

| Y-axistravel | mm | 400 | |

| Y-axistravel | mm | 330/330 | |

| Distance from spindle nose to table surface | mm | 150-480 | |

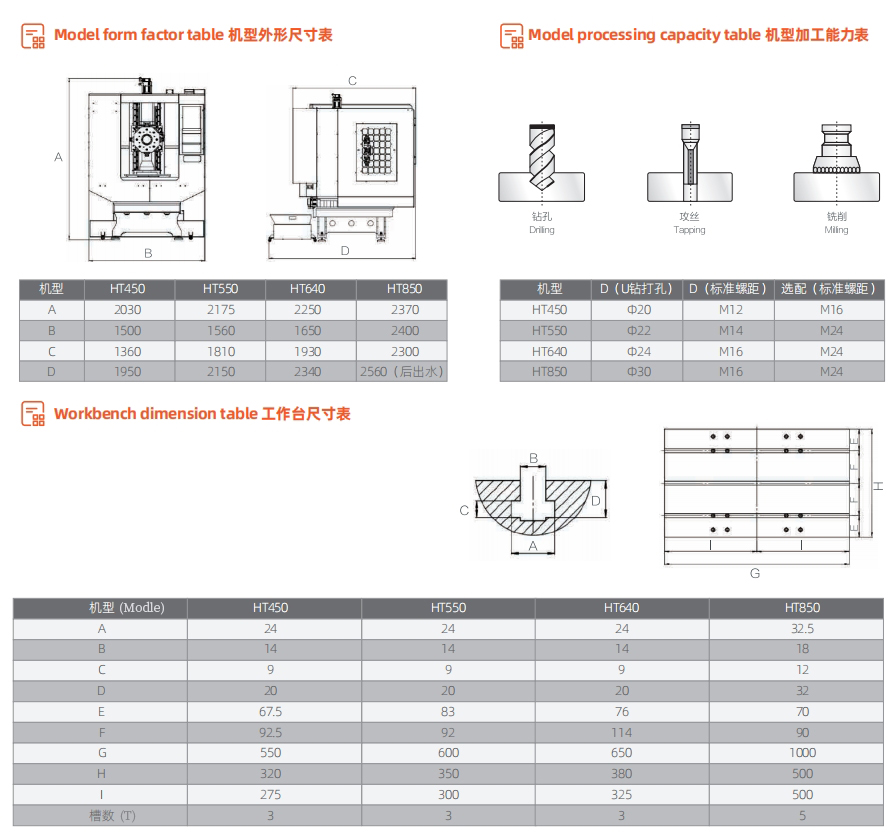

| Workbench | Table size(Xdirection) | mm | 700 |

| (Y direction) | 400 | ||

| T-slot (numberofslots/width/spacing) | 3/14/25 | ||

| Maximum loadof worktable | kg | 300 | |

| Feed | Rapid feed rate X/Y/Z | m/min | 48/48/48 |

| positioning accuracy | mm | ±0.005/300 | |

| Repeatability | mm | ±0.003/300 | |

| Cutting feed rate | mm/min | 5-20000 | |

| Automatic Tool Change System | Tool magazine capacity | T | 21 |

| Maximum adjacent tool Diameter | mm | Φ50-Φ120 | |

| Tool changetime T to T | sec. | 1.6 | |

| Other | Machine size | mm | 1750*2388*2216 |

| Machineweight (approximately) | kg | 3000 | |

| Controller | Mitsubishi/FANUC | ||

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | Mitsubishi | Japan | M80B |

| 2 | Spindle Motor | Mitsubishi | Japan | D7.5/120 |

| 3 | X/Y/Z Axis | Mitsubishi | Japan | HG154S HG154S HG224BS |

| 4 | Ball Screw (X/Y/Z Axis) | PMI/THK | Taiwan/Japan | 28/28/32 |

| 5 | Linear Guide (X/Y/Z Axis) | PMI/THK | Taiwan/Japan | 30/30/35 |

| 6 | Ball Screw Bearing | NACHI | Japan | |

| 7 | Lubrication System | HEGU | Joint Venture | |

| 8 | Spindle | VYU CHENG/DEJO | Taiwan | |

| 9 | Tool Magazine | SANJET/DEJIE | Taiwan | |

| 10 | Cooling Pump | STAIRS | Taiwan | |

| 11 | Pneumatic Components | SMC | Japan | |

| 12 | Transformer | LUHO | ||

| 13 | Electrical Components | SCHNEIDER | France | |

| 14 | Telescopic Cover | ETEK/KEYARROW | ||

| 15 | Rear Chip Punching | XM |