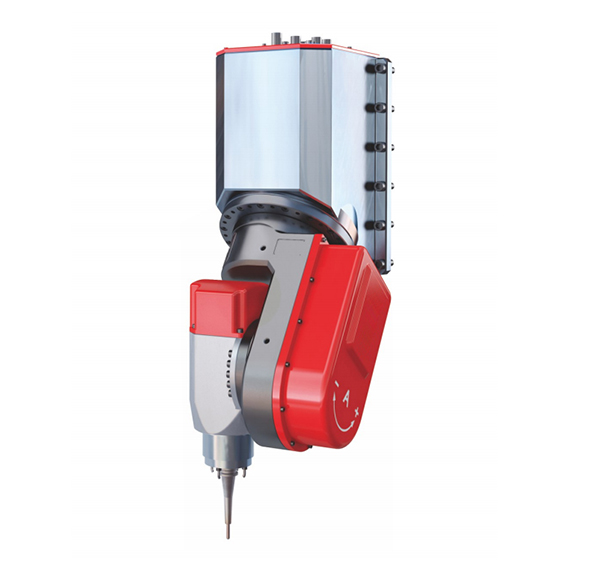

Mini Five-Axis Double Swing Head

- Five-Axis Double Swing Head advantages

With automatic adjustment of backlash, life-long maintenance free, continuous work for 20,000 hours without loss of accuracy; Small size, high speed, high rigidity, high precision, simple structure, wide processing range, etc. - Scope of application:

Rail vehicles and parts processing for the aerospace industry; Mold design, teaching, military, wind power generation; Design modeling - Processing materials:

Surface treatment of titanium, steel and castings; Aluminum, Zamak, carbon fiber, composite material processing; Plastic, wood, etc.

SKU:

TZCH-L1

Categories: CNC Angle Heads, CNC Parts & Tools

Tags: 5 Axis angle head,angle head, milling angle head

Brand: JHXinMai

share:

| Item | TZCH-L1 | TZCH-L2 | TZCH-L3 | TZCH-L5 |

|---|---|---|---|---|

| C axis swivel range /Speed | ±360° /220°S | ±360° /220°S | ±360° /220°S | ±360° /180°S |

| A axis swivel range/Speed | ±125° /220°S | ±125° /220°S | ±115° /220°S | ±115° /180°S |

| A axis shaft continuous output torque | 420NM | 420NM | 980NM | 1480NM |

| A-shaft emergency braking torque | 1100NM | 1100NM | 2530NM | 3780NM |

| Continuous torque output from the C-axis | 420NM | 420NM | 980NM | 1480NM |

| C-axis emergency braking torque | 1100NM | 1100NM | 2530NM | 3780NM |

| A/C axis servo motor – Yaskawa, | — | — | — | — |

| A/C repeatability positioning accuracy | ±6° | ±6° | ±6° | ±6° |

| A/C linkage machining accuracy | 0.6′ | 0.6′ | 0.6′ | 0.6′ |

| Swing electric spindle/speed/S1 torque | 27000rpm/ 10.8nm | 20000rpm/ 39.6nm | 20000rpm/ 50nm | 18000rpm/ 105nm |

| Swing electric spindle/power S1 | 12.5KW | 15KW | 15.7KW | 30KW |

| Tool shank | HSK-E50/E40/ BT30 | HSK-A63/HSK-F63 | HSK-A63 | HSK-A63 |

| Cutting mode | Hydraulic pressure/60Pa | Hydraulic pressure/60Pa | Hydraulic pressure/60Pa | Hydraulic pressure/60Pa |

| Weight | 245KG | 275KG | 420KG | 450KG |