H50 High Speed Heavy Horizontal Milling Machine

- High-speed, high-rigidity structural design;

- Optimal space utilization and user-friendly operation;

- High production efficiency with great chip evacuation;

- High-speed, high-precision performance control system;

share:

High-Performance Spindle

Spindle Center Air Blow: Keeps the tool holder clean, enhancing machining accuracy.

Spindle Air Curtain Protection: Prevents dust from entering the spindle bearings, extending the lifespan of the spindle.

Integrated Nozzles Around the Spindle: This design eliminates the need to adjust a single nozzle when machining complex shapes, providing consistent cooling and cleaning.

Guideways and Ball Screws

Three-Axis Guideways: Utilizes German SCHNEEBERGER R55 high-speed heavy-duty linear guideways, offering high rigidity, high load capacity, high speed, and low thermal deformation.

Three-Axis Ball Screws: Employs Japanese THK SBN50X ultra-high-speed, ultra-quiet ball screws, with a DN value up to 2,200,000, ensuring low noise, minimal thermal rise, high speed, and rigidity.

Control System

High-Performance Control System: Equipped with the FANUC Series Oi-MD, providing high precision, increased productivity, and enhanced safety in machining processes.

Expandable Memory: The control system supports CF card integration, allowing for increased external memory capacity.

Comprehensive Error Compensation: Various error compensation features enable high-precision machining, minimizing deviations and enhancing accuracy.

Oil-Water Separator

Efficient Oil-Water Separation: Prolonged oil contamination in the coolant tank can lead to deterioration and odors. The separator effectively removes oil contamination, keeping the coolant tank clean.

Tool Magazine

Horizontal Machining Center Tool Magazine: Features a cam-dividing mechanism with high precision and low failure rates. The separated tool claws ensure quick tool changes with stable performance and easy maintenance. Its modular design allows for customization based on the specific production needs of the customer.

Electrical Cabinet

Sealed Electrical Cabinet: Prevents oil mist and water vapor from entering, protecting electrical components from moisture and potential short circuits or damage.

Pneumatic System

External Pneumatic System: The air compression system is mounted externally on the protective casing, making it easy to manage and maintain.

Lubricator Positioning: Designed for convenient oil addition, the lubricator is positioned away from electrical components to ensure safety and ease of use.

| PROJECT | UNIT | H50 | |

|---|---|---|---|

| Workbench | Table size | mm | 500*500 |

| Pallet indexing | (°) | 1(optional 0.001,5) | |

| T-slot | mm | 100*18*5 | |

| Max. swing diameter | mm | Φ1200 | |

| Table load | kg | 500 | |

| Travel | X/Y/Z travel | mm | 800/600/650 |

| Spindle nose to table center | mm | 150-800 | |

| Spindle center to table surface | mm | 80-680 | |

| Spindle | Spindle taper | BT50 | |

| Spindle speed | rpm | 6000 | |

| Spindle bearings | mm | 5 rows of 7020 bearings (3 front – 2 rear layout) | |

| Spindle torque(Rated/Peak) | N.m | 143/236 | |

| Feed Rate | X/Y/Z cutting feed | mm/min | 20000 |

| X/Y/Z rapid feed | mm/min | 10000 | |

| Accuracy | Positioning accuracy | mm | ≤0.008 |

| Repeat positioning accuracy | mm | ≤0.005 | |

| Automatic Tool Change System | Toolholder type | MAS BT No.50 | |

| Tool Magazine capacity | T | 24(standard)/40(optional) | |

| Max. tool diameter | mm | Φ120(Φ250 oval space) | |

| Max. tool length | mm | 400 | |

| Max. tool weight | kg | 20 | |

| Tool change time | S | 4.75 | |

| Spindle Motor | Belt spindle motor | kw | 15/18.5 |

| Other | Supply Voltage | 380V±10% three-phase four-wire system | |

| Supply frequency | Hz | 50±1% | |

| Power requirement | kva | 50 | |

| Air source pressure/flow | Mpa/L/min | 0,5-0.8/600 | |

| Machine weight | kg | 11000 | |

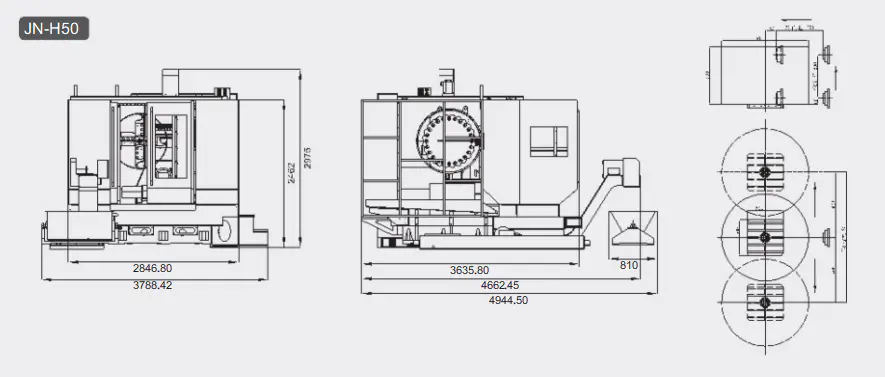

| Machine size | mm | 3800*4960*2980 | |

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | FANUC | Japan | 0I-MF |

| 2 | Spindle Motor | FANUC | Japan | βiIP30/8000 |

| 3 | X/Y/Z/Fourth Axis | FANUC | Japan | βis30/2000 βiS40B/2000 βiS40/2000 βis22/3000 |

| 4 | Ball Screw (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 50/50/50 |

| 5 | Linear Guide (X/Y/Z Axis) | PMI/HIWIN | Taiwan | X45 /Y45/ Z55 |

| 6 | Screw Coupling | JANETECH | Taiwan | |

| 7 | Ball Screw Bearing | NACHI | Japan | |

| 8 | Motorized Lubrication System | HEGU | Joint Venture | |

| 9 | Spindle | POSA | Taiwan | |

| 10 | Tool Magazine | CHNCIT/OKADA | China | |

| 11 | Cooling Pump | STAIRS | Taiwan | |

| 12 | Pneumatic Components | SMC | Japan | |

| 13 | Transformer | LUHO | ||

| 14 | Electrical Components | SCHNEIDER | France | |

| 15 | Telescopic Cover | CHNCIT/ETEK | Taiwan | |

| 16 | Screw + Chain Plate Type Chip Conveyor | CHNCIT | ||

| 17 | Machine External Sheet Metal | CHNCIT | ||

| 18 | Fourth Axis | DETRON | Taiwan | 500*500 |

| 19 | Hydraulic Station | 7OCEAN | Taiwan |

| Standard Configuration | Optional Configurations |

|---|---|

| Twin-screw” Chain Chip Removal Device | |

| Automatic Lubrication System | |

| Spindle Center Blowing | |

| Spindle Air Curtain Protection | |

| ATC Tool Magazine 24T | ATC tool magazine storage number 32T/40T/60T |

| Oil mist recovery device | |

| Spindle center outlet | |

| Machine Leveling System | |

| Cutting Fluid Cooling System | |

| Three-color Warning Light | |

| Water Gun | |

| Chassis Flushing Device | |

| Automatic Power-off Device | |

| Tool Box | |

| Water Tank | |

| Gearbox/BF |