IV850 Vertical CNC Machining Center Hot Sale

CNC Machining Center Feature:

- Machining flexibility for various operations like milling, drilling, and tapping;

- High precision and efficiency;

- Three system choices: Fanuc, mitsubishi, and siemens 828d, with standard original motors;

- Belt or Direct type options available for specific product machining requirements.

share:

Spindle

High-Performance Spindle Structure: The spindle features a high-power, high-torque, high-speed, high-precision structure, with options for 8,000/12,000 belt or Direct type.

Automatic Tool Changer (ATC)

24-Tool Capacity: The tool change time is 2.5 seconds, enabling rapid tool changes, enhancing production efficiency, and minimizing non-machining time.

Electrical Cabinet

Thermal Separation: The electrical cabinet is designed with thermal separation, eliminating the need for radiators and reducing dust ingress.

Coupler

Imported from Taiwan: The couplings use advanced German technology, significantly extending the lifespan of the coupling.

Chip Conveyor

Standard Rear Discharge: The standard rear chip flushing facilitates chip removal.

Integrated Casting

Integrated Saddle and Motor Base: Strengthens rigidity and machine tool precision.

| Project | Unit | Specification A | Specification B | |

|---|---|---|---|---|

| Workbench | Table size | mm | 1000*500 | 1000*500 |

| Max. workpiece size | mm | 800*500 | 800*500 | |

| T-slot | mm | 100*18*5 | 100*18*5 | |

| Table load | kg | 500 | 500 | |

| Travel | X/Y/Z travel | mm | 800/500/500 | 800/500/500 |

| Spindle nose to table surface | mm | 150-650 | 150-650 | |

| Spindle center to column surface | mm | 520 | 520 | |

| Spindle | Spindle taper | BT40 | BT40 | |

| Spindle speed | rpm | 12000 | 8000 | |

| Spindle drive method | Direct type | Belt type | ||

| Spindle Motor | Spindle drive method | kw | 7.5 | 11 |

| Feed Rate | X/Y/Z cutting feed | mm/min | 1-10000 | 1-10000 |

| X/Y/Z rapid feed | mm/min | 36000/36000/36000 | 36000/36000/36000 | |

| Accuracy | Positioning accuracy | mm | 0.008 | 0.008 |

| Repeat positioning accuracy | mm | 0.005 | 0.005 | |

| Automatic Tool Change System | Tool Magazine capacity | T | 24 | 24 |

| Tool change method | Disc arm type | Disc arm type | ||

| Max. tool diameter | mm | Φ80 (Φ150 oval space) | Φ80 (Φ150 oval space) | |

| Max. tool length | mm | 250 | 250 | |

| Max. tool weight | kg | 7 | 7 | |

| Toolholder type | BT40 | BT40 | ||

| Tool change time | S | 2.5(T-T) | 2.5(T-T) | |

| Other | Air pressure demand | kg/cm2 | 6 | 6 |

| Max. Processing Speed | mm/min | 10000 | 10000 | |

| Cooling pump | W | 1270 | 1270 | |

| Power requirement | kva | 15 | 15 | |

| Machine weight | kg | 4500 | 4500 | |

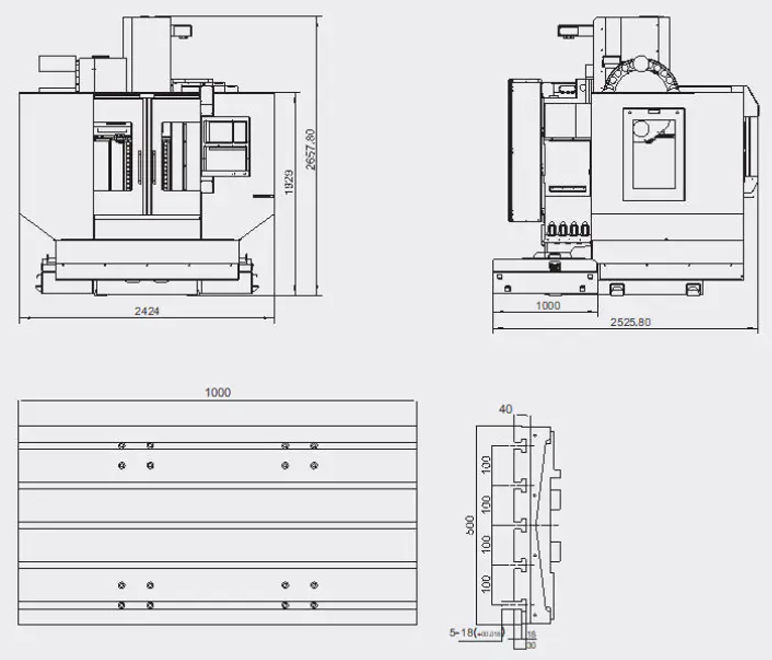

| Machine size | mm | 2424*2525*2657 | 2424*2525*2657 | |

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | Mitsubishi | Japan | M80B |

| 2 | Spindle Motor | Mitsubishi | Japan | D11/100 |

| 3 | X/Y/Z Axis | Mitsubishi | Japan | HG224S |

| HG224S | ||||

| HG303BS | ||||

| 4 | Ball Screw (X/Y/Z Axis) | PMI/THK | Taiwan/Japan | 3616/3616/4016 |

| 5 | Linear Guide(X/Y/Z Axis) | PMI/THK | Taiwan/Japan | 35/35/35 |

| 6 | Screw Coupling | LONGCHUANG | Joint Venture | |

| 7 | Ball Screw Bearing | NACHI | Japan | |

| 8 | Lubrication System | HEGU | Joint Venture | |

| 9 | Boosting Cylinder | HINAKA | Taiwan | |

| 10 | Spindle | VYU CHENG/ROYAL | Taiwan | |

| 11 | Tool Magazine | CHNCIT | China | |

| 12 | Cooling Pump | STAIRS | Taiwan | |

| 13 | Air Tank | China | ||

| 14 | Pneumatic Components | SMC | Japan | |

| 15 | Transformer | LUHO | ||

| 16 | Electrical Components | SCHNEIDER | France | |

| 17 | Telescopic Cover | XM | ||

| 18 | Rear Chip Punching | XM | ||

| 19 | Machine External Sheet Metal | XM |

| Standard Configuration | Optional Configuration |

|---|---|

| Mitsubishi M80B | FANUC Oi-MFPLUS, Siemens 828D system |

| Spindle (Taiwan brand) | Column heightening |

| ATC tool magazine storage 24T | Chain plate chip removal |

| Guide rail (Taiwan brand) | Automatic door |

| Ball Screw Bearing (Taiwan/Japan) | Center water discharge |

| Retractable shroud (Taiwan brand) | Tool setting instrument |

| Pneumatic Components (Taiwan brand) | Water gun |

| Oil cooler |