CH506MSY Double-Spindle Turning Milling Compound CNC Lathe

CNC Lathe Feature:

- Double-Spindle structure with high rigidity and stability;

- Large table area for efficient machining;

- Combined turning and milling machining process, to complete the process of machining in one clamping.

share:

Spindle

The spindle is available in a high-power, high-torque, high-speed, high-precision built-in direct-drive motorized spindle configuration or a rear direct-drive motorized spindle configuration.

CNC Control System

We utilize the Taiwan SYNTEC brand. The latest 220 Series can control up to four axes groups, equipped with comprehensive multi-axis control and multi-program application features, enhancing machine flexibility.

The new multi-axis group interface meets the requirements for synchronized machining in complex machines.

X/Z Drive

The X, Z, and Y axes utilize Japan’s THK precision ball screw transmission in conjunction with THK linear ball guides, offering great dynamic performance.

The rapid feed rates for the X and Z axes are 20m/min each. Both the ball screws and guides use centralized oil lubrication, significantly reducing lubricant consumption and greatly extending cutting fluid life.The fully enclosed protective cover prevents the spillage of chips and dust, ensuring no pollution to the working environment.

Gantry Structure

High Rigidity and Stability: The gantry structure offers extremely high rigidity and stability, suitable for heavy-duty cutting and the processing of large-sized workpieces.

Large Worktable: Capable of accommodating and processing large-sized workpieces, it is ideal for the manufacture of large components in aerospace, aviation, and automotive industries.

Turn-Mill

Versatility: Integrating turning, milling, drilling, tapping, and various other machining processes into a single machine, enabling complete processing of complex parts in one setup.

Efficient Machining: Capable of completing multiple processes in a single machining cycle, significantly reducing machining time and enhancing production efficiency.

| No. | Parameter name | Unit | Parameters |

|---|---|---|---|

| 1 | Max. swing over bed | mm | 300 |

| 2 | Max. turning length | mm | 650 |

| 3 | Spindles | 2 | |

| 4 | Spindle speed | r/min | 30~6000 |

| 5 | Spindle nose taper | A2-5 | |

| 6 | Spindle bore | mm | 46 |

| 7 | Tool holder | set | 2 |

| 8 | X1 axis travel | mm | 800 |

| 9 | X2 axis travel | mm | 800 |

| 10 | Y1 axis travel | mm | 220 |

| 11 | Y2 axis travel | mm | 220 |

| 12 | Z1 axis travel | mm | 600 |

| 13 | Z2 axis travel | mm | 600 |

| 14 | Rapid feed | mm/min | 24000 |

| 15 | Cutting feed | mm/min | 10000 |

| 16 | Left turret turning tools | 5 | |

| 17 | Right turret turning tools | 4 | |

| 18 | Left turret milling tools | 4 | |

| 19 | Right turret milling tools | 4 | |

| 20 | OD tools size | mm | 16× 16 |

| 21 | Boring tools diamater | mm | 20 |

| 22 | CNC system | SYNTEC | |

| 23 | Spindle (max. torque) | N.M | 125 |

| 24 | X-axis motor (max. torque) | N.M | 11 |

| 25 | Z-axis motor (max. torque) | N.M | 18.6 |

| 26 | Y-axis motor (max. torque) | N.M | 11 |

| 27 | Sub spindle(max. torque) | N.M | 11 |

| 28 | Spindle (Power) | KW | 17.5 |

| 29 | X-axis motor (power) | KW | 2.4 |

| 30 | Z-axis motor (power) | KW | 3.9 |

| 31 | Y-axis motor (power) | KW | 2.4 |

| 32 | Sub spindle(power) | KW | 2.3 |

| 33 | Voltage | V | 220 |

| 34 | Frequency | HZ | 60 |

| 35 | Air pressure | Mpa | 0.5 |

| 36 | Oil pressure pump | KW | 1.5 |

| 37 | Lubricating oil pump | KW | 0.004 |

| 38 | Water pump | KW | 0.37 |

| 39 | Power supply | KVA | 20 |

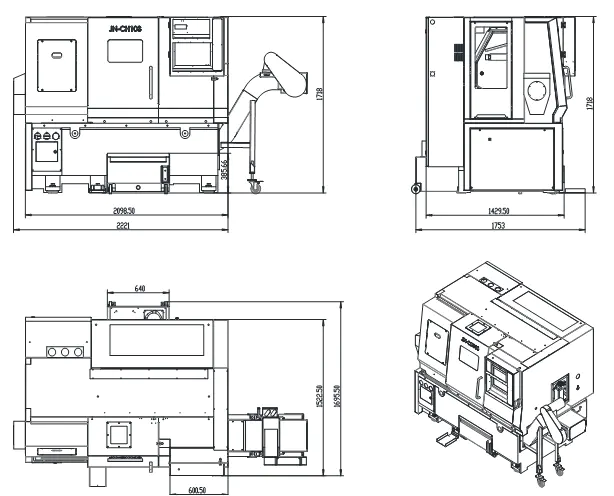

| 40 | Machine size (L*W*H) | mm | 3036 × 1982×2157 |

| 41 | Machine weight | kg | 7100 |

| Item | Spec | Brand Origin | Brand | |

|---|---|---|---|---|

| CNC Control System | 22TB | Taiwan | SYNTEC | |

| Servo Motors | X-axis | AM11 | Taiwan | SYNTEC |

| Y-axis | AM11 with holding brake | |||

| Z-axis | AM18 | |||

| Power head | AM11* | |||

| Ball Screws | X-axis | φ32 | Japan | THK |

| Y-axis | φ32 | |||

| Z-axis | φ40 | |||

| Linear Guide | X-axis | 35 | Japan | THK |

| Y-axis | 35 | |||

| Z-axis | 35 | |||

| Screw Couplings | X-axis | ALS-055-R-20B-24B | Japan | THK |

| Y-axis | ALS-055-R-20B-24B | |||

| Z-axis | ALS-055-R-25B-35B | |||

| Ball Screw Bearing | S6206 | Japan | NTN | |

| S7206 | ||||

| Spindles | A2-5-170-D-02 | CHNCIT | ||

| Transformer | 20KWA | Joint Venture | LUHO | |

| Powerheads | TX-ER25-YT150-P4 | Taiwan | JANETECH | |

| Electrical Components | Germany | SCHNEIDER | ||

| Pneumatic Components | Japan | SMC | ||

| Lubrication System | China-Japan Joint Venture | HEGU | ||

| Shield | Retractable Shield | China | XM | |

| Roller shutter shroud | China | XM | ||

| Chip Conveyor | Chain Plate Type Chip Conveyor | China | XM | |