CH108 High Speed CNC Lathe Machining For Turning Drilling Milling

CNC Lathe Machining Feature

- High-speed, high-rigidity structural design;

- Optimal space utilization and user-friendly operation;

- High production efficiency with great chip evacuation;

- High-speed, high-precision performance control system;

- Fully automatic hydraulic tailstock and hydraulic chuck.

share:

Spindle

The spindle center features an air blow system to keep the tool holder clean, thereby improving machining accuracy. The T500 drilling and tapping center’s three axes offer comprehensive software functionality for high-speed, high-precision machining with network capabilities. The system design employs a modular structure extensively, making it easy to disassemble and assemble. Highly integrated control boards greatly enhance reliability and facilitate maintenance and replacement. There are comprehensive protective measures in place. FANUC employs great protection circuits for its systems.

The two supporting journals A and B of the spindle have a roundness tolerance of 0.005mm, a radial runout tolerance of 0.005mm, and a surface roughness of Ra 0.4mm. The dimensional accuracy of the supporting journals is IT5. With strong dynamic and static rigidity, the spindle can achieve a high rotational speed of up to 5000 RPM. The spindle is made of materials independently developed by our over many years, featuring high surface hardness and fatigue strength. Moreover, the nitriding layer offers advantages such as corrosion resistance and minimal heat treatment deformation.

Tool Magazine

The tool magazine can store up to 12 tools, fulfilling various machining needs, significantly reducing machining time and production costs. During tool changes, the tools accurately stop at the tool change position, with a repeat positioning accuracy of ±1. The tool change speed is only 0.52 seconds.

Chuck

The hydraulic chuck features a fully enclosed structure, with all mating surfaces equipped with dust-proof functionality, offering high clamping accuracy, long service life, strong clamping force, and a wide clamping range. The hydraulic chuck improves upon the limitations of traditional hydraulic chucks, which include small clamping force and unstable strength. Moreover, the clamping force is stable and reliable.

Guide Rail

The guide rail uses high-rigidity rollers as rolling elements, with the length of each roller exceeding 1.5 times its diameter, achieving higher rigidity. It provides four-direction equal load capacity. To ensure that the LM block on all four operational directions (radial, reverse radial, and lateral) possesses the same rated load, each roller row is designed with a contact angle of 45 degrees, offering high rigidity in all directions. The use of a roller retainer eliminates mutual friction between rollers, improving grease retention capability and allowing for long-term operation without maintenance.

Electrical Components

Schneider materials are used, whether for PC materials or internal terminal blocks, ensuring high quality. They provide high stability and can adapt to fluctuations in AC system voltage, suppressing noise interference in the power network to a certain extent. The system offers high safety with reliable and effective interlocking, good insulation for electrical devices, complete protection, and secure grounding.

Chip Conveyor

The integrated internal protective cover is designed to be simple, practical, and long-lasting. During machining, iron chips and cutting fluids that splash out directly fall onto the chip conveyor along the 30-degree protective cover slope. The chip conveyor separates the cutting fluid from the machining chips, discharging the chips out of the machine tool, ensuring that iron chips do not accumulate inside the machine, thus improving work efficiency.

Hydraulic Tailstock

The hydraulic tailstock allows for systematic control of the tailstock’s center advancing and retracting, enabling automatic loading and unloading in conjunction with the hydraulic chuck, enhancing clamping efficiency. The machine tool’s dedicated hydraulic station provides more stable clamping force and offers high energy transmission, great control performance, fast response speed, minimal oil leakage, and reduced maintenance workload.

| Project | Unit | JN-CH108 |

|---|---|---|

| Max. swing over bed | mm | 480 |

| Max. turning diameter | mm | 210 |

| Max. turning length | mm | 480 |

| Max. bar capacity | mm | 52 |

| Spindles | 1 | |

| Spindle speed | r/min | 30-4000 |

| Min. orientation accuracy | 0.001 | |

| Spindle nose | A2-6 | |

| Spindle Bore | mm | 63 |

| Spindle bearing diameter | mm | 100 |

| Spindle power(continuous/30min overload) | KW | 11/15 |

| Tailstock travel | mm | 435 |

| Tailstock arbor diameter | mm | 75 |

| Tailstock morse taper | mm | MT.4 |

| Arbor travel | mm | 100 |

| Turret type | T12 | |

| X travel | mm | 180 |

| Z travel | mm | 530 |

| X/Z rapid feed | mm/min | X:24000 Z:24000 |

| Cutting feed | mm/min | 10000 |

| Manual cutting feed | mm/min | 0~1200 |

| Tool Capacity | 12 | |

| Diameter for boring tools | mm | 40 |

| Tool change time | s | 0.52 |

| Project | Unit | JN-CH108 |

|---|---|---|

| Power supply | ||

| Power supply | KVA | 20 |

| Power voltage | V | 380 |

| Frequency | HZ | 50/60 |

| Air pressure | Mpa | 0.5 |

| Pneumatic flow rate | L/min | 10 |

| Tank capacity | ||

| Oil tank capacity | L | 40 |

| Oil pressure | L | 2 |

| Water Tank | L | 200 |

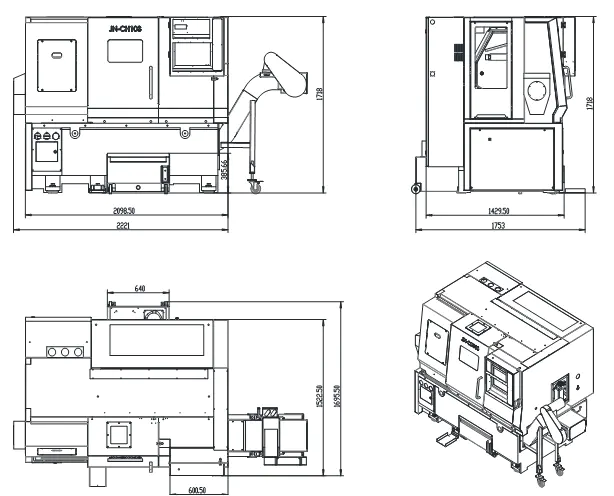

| Dimension | ||

| Lathe height | mm | 1709 |

| Floor space | mm | 2219× 1565 |

| Lathe weight | T | 3.95 |

| Item | Specifications | Brand Origin | Brand |

|---|---|---|---|

| Control System | 0I-TF | Japan | FANUC |

| Spindle Motor | βiI 12/10000 | Japan | FANUC |

| Servo Motor (X-axis) | βis 8/3000 | Japan | FANUC |

| Servo Motor (Z-axis) | βis 22/2000 | Japan | FANUC |

| Ball Screw (X-axis) | 32 | Japan/Taiwan | PMI/ HIWIN |

| Ball Screw (Z-axis) | 40 | Japan/Taiwan | PMI/ HIWIN |

| Roller Guide (X-axis) | SRG-30R-QZ-620L | Japan | THK/ PMI |

| Roller Guide (Z-axis) | SRG-35R-QZ-1080L | Japan | THK/ PMI |

| Screw Coupling (X-axis) | 19-20 | Taiwan | JANETECH |

| Screw Coupling (Z-axis) | 28-35 | Taiwan | JANETECH |

| Ball Screw Bearings | 6305Z | Japan | NACHI |

| 6206 | |||

| BST25*62-1BP4 | |||

| BST30*62 | |||

| Spindle | TAC-20-KD-B | Taiwan | POSA |

| Transformer | 20KWA | Joint Venture | LUHO |

| Turret | Germany | GPM | |

| Electrical Components | Germany | Schneider | |

| Pneumatic Components | Japan | SMC | |

| Lubrication System | Sino-Japanese JV | HEGU | |

| Protection Cover | Telescopic Cover | China | YIDE |

| Rolling Cover | China | AEGIS | |

| Chip Conveyor | Chain Plate Chip Conveyor | China | CHNCIT |

| Hydraulic Tailstock | |||

| Boring Tool Holder | 4 pcs of Φ40 | ||

| End Face Tool Holder | 2 pcs | ||

| Diameter Change Sleeve | Φ8, Φ10, Φ12, Φ14, Φ16, Φ20, Φ25, Φ32 each 1 | ||

| Tool Pressure Block (Upper and Lower) | 8 |