Categories

Recommended Products

JN-NV856 Vertical Machining Center

- High-speed, heavy-duty cutting, high-precision structural design;

- Short-nose spindle with high precision and rigidity;

- Spindle center air blast and air curtain protection;

- High-speed, high-precision performance control system;

- Fully enclosed protection.

share:

High Rigidity Structure

Robust Bed and Columns: Constructed from high-strength cast iron or other alloy materials, ensuring the machine tool has adequate rigidity and vibration resistance, capable of withstanding large cutting forces.

Reinforced Spindle Box: The spindle box design is optimized to further enhance rigidity and stability.

Cutting Capability

High-Power Spindle: Equipped with a high-power spindle motor capable of heavy-duty cutting, suitable for processing hard materials and large workpieces.

High-Torque Drive System: Ensures stable cutting forces during low-speed, heavy-duty cutting operations.

High Precision

Precision Ball Screws: Utilizes high-precision ball screws to ensure axial movement accuracy.

Linear Guideways: High-quality linear guideway systems provide smooth movement and high-precision positioning.

Large Worktable

Large Worktable: Capable of accommodating and processing large workpieces, suitable for manufacturing large parts in industries such as aerospace, aviation, and energy equipment.

High Load-Bearing Capacity: The worktable offers high load-bearing capabilities to stably support heavy workpieces.

High Level of Automation

Automatic Tool Changer (ATC): Equipped with a 24-tool automatic tool-changing system for quick tool swaps, enhancing production efficiency.

CNC System: Features advanced CNC systems (FANUC/Siemens/Mitsubishi optional) that support complex process programming and automated machining.

| Item | Unit | Specification | ||

|---|---|---|---|---|

| Working Table | Table size | mm | 1000*550 | |

| T-slot | mm | 100*18*5 | ||

| Table load | kg | 700 | ||

| Travel | X/Y/Z Axis travel | mm | 850/550/600 | |

| Spindle nose to table surface | mm | 150-750 | ||

| Spindle center to column surface | mm | 600 | ||

| Spindle | Spindle taper | BT40 | ||

| Spindle speed | rpm | 8000 | ||

| Spindle drive mode | Belt type | |||

| Spindle Motor | Spindle Motor | kw | 15-18.5 | |

| Feed rate | Cutting feed (X/Y/Z Axis) | mm/min | 1~10000 | |

| Rapid feed speed (X/Y/Z Axis) | m/min | 36/36/36 | ||

| Precision | Positioning accuracy | mm | 0.008 | |

| Repeat positioning accuracy | mm | 0.005 | ||

| Automatic tool change system (Optional) |

Tool Magazine capacity | T | 24 | |

| Tool change mode | ||||

| Max. tool diameter | mm | Φ78 | ||

| Max. tool diameter with adjacent vacant | Φ150 | |||

| Max. tool length | mm | 250 | ||

| Max. tool weight | kg | 7 | ||

| Toolholder type | BT40 | |||

| Others | Air pressure | kg/cm2 | 5-7 | |

| Power requirement | KVA | 25 | ||

| Machine weight (approx.) | kg | 5800 | ||

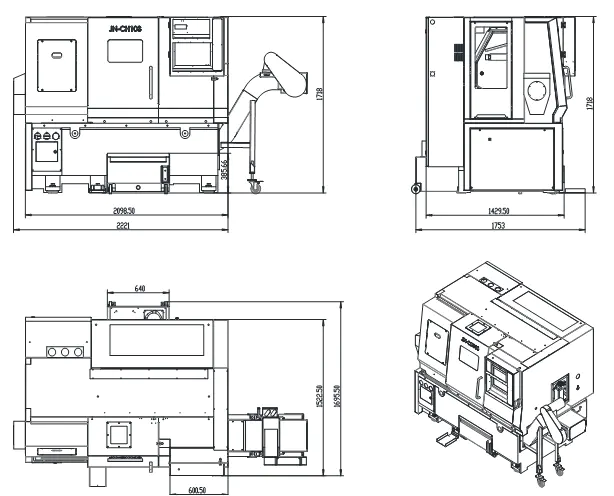

| Machine size | mm | 2560*3150*2700 (including water tank) |

||

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | FANUC | Japan | FANUC 0i-MF(5) |

| 2 | Spindle Motor | FANUC | Japan | βiI15/8000 |

| 3 | X/Y/Z Axis | FANUC | Japan | βis22/3000 βis22/3000 βis22B/3000 |

| 4 | Ball Screw (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 40/40/40 |

| 5 | Linear Guide (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 45/45/45 |

| 6 | Screw Coupling | JANETECH | Taiwan | |

| 7 | Ball Screw Bearing | NACHI | Japan | |

| 8 | Lubrication System | HEGU | Joint Venture | |

| 9 | Boosting Cylinder | HINAKA | Taiwan | |

| 10 | Spindle | POSA | Taiwan | |

| 11 | Tool Magazine | CHNCIT | China | |

| 12 | Cooling Pump | STAIRS | Taiwan | |

| 13 | Air Tank | China | ||

| 14 | Pneumatic Components | SMC | Japan | |

| 15 | Transformer | LUHO | ||

| 16 | Electrical Components | SCHNEIDER | France | |

| 17 | Telescopic Cover | CHNCIT | ||

| 18 | Rear Chip Punching | CHNCIT | ||

| 19 | Machine External Sheet Metal | CHNCIT |

| Optional Components | Optional Part Parameters |

|---|---|

| Numerical Controls | FANUC/Mitsubishi |

| Transmission | Direct Connect/Belt |

| Spindle speed | 8000/12000 |