This guide offers insights into choosing between a Horizontal Machining Center (HMC) and a Vertical Machining Center (VMC). It details the characteristics of each type, helping readers make an informed decision based on their machining requirements.

This article focuses on gantry machining centers, highlighting their significance as the powerhouse for large - workpiece machining. It details their features and capabilities that enable efficient processing of large components, crucial for industries dealing with substantial workpieces.

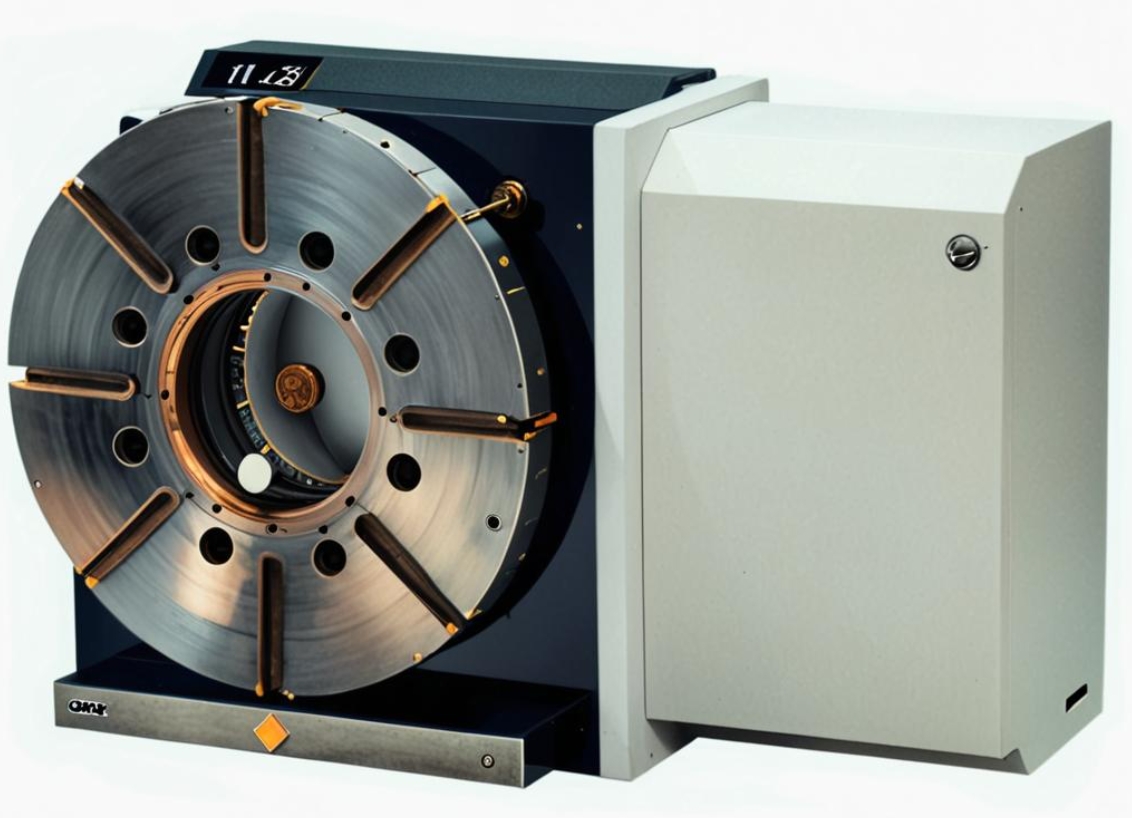

On the working principle of four - axis rotary tables. It also presents their diverse practical applications across various manufacturing fields, highlighting how the unique functionality of these rotary tables enables enhanced machining capabilities, improved precision, and more efficient production processes in different industrial scenarios.

This article focuses on the structural features of column moving machining centers. It delves into the key elements that define these machining centers, such as their column movement mechanism, which offers unique advantages in terms of precision, flexibility, and work envelope. Understanding these structural features is crucial for those in the machining industry, as it enables better utilization of column moving machining centers and helps in optimizing manufacturing processes to achieve higher quality and efficiency in machining operations.

AI and IoT are transforming machining centers, improving efficiency, predictive maintenance, and quality control. AI enables real-time production adjustments, while IoT enhances machine communication, supply chain integration, and remote monitoring. As autonomous and sustainable manufacturing grow, companies adopting these technologies will gain a competitive edge in the global market.

Explore how robotics is transforming industrial manufacturing, driving efficiency, sustainability, and innovation in the robot era. Learn about opportunities and challenges ahead.

This article provides a comprehensive guide to selecting the right machining center for your business. It covers important technical aspects such as spindle speed, precision, and work envelope, as well as budget considerations like initial costs, operating expenses, and ROI. Tips on finding the right balance and considering second-hand options are also included, helping businesses make an informed, cost-effective decision.

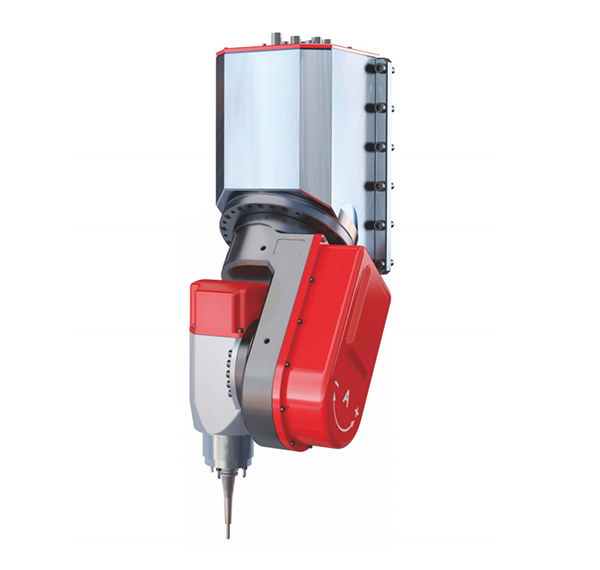

Tool replacement in CNC machining is crucial for efficiency. Low tool change efficiency can delay production and increase costs. This article explores the challenges of tool changing and provides practical solutions to optimize the process.