Introduction

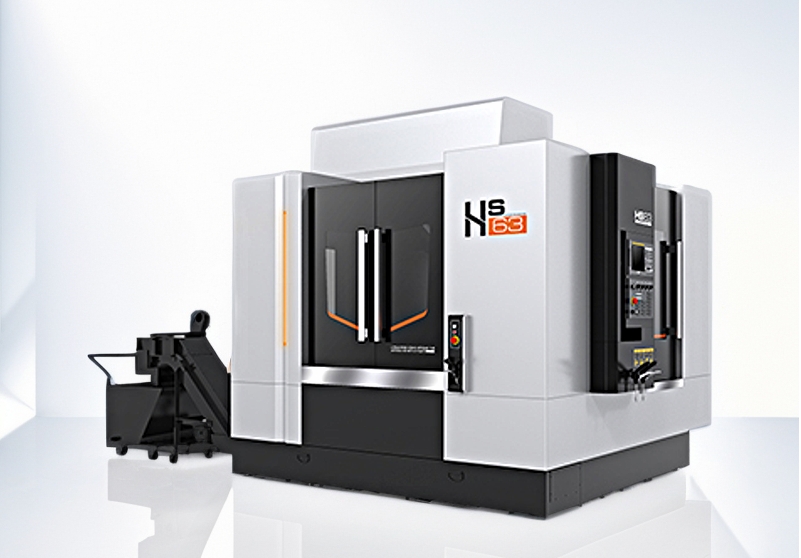

Horizontal machining centers, as indispensable high-efficiency and high-precision CNC machine tools in modern manufacturing, play a crucial role in multiple industrial fields with their outstanding flexibility and extensive processing capabilities. It can not only handle common tasks in traditional mechanical processing, but also cope with more complex and precise processing requirements. The following will explore in detail the types of parts that horizontal machining centers can process and their applications in various fields

Complex multi-faceted parts

One of the most notable features of a horizontal machining center is that it can complete the processing of multiple surfaces and holes in a single clamping, which is particularly suitable for complex parts with multiple planes and hole systems. For instance, key automotive components such as the transmission case and engine block are difficult to be efficiently completed by traditional machine tools due to their complex shapes, numerous processing procedures and high precision requirements. The horizontal machining center, through its multi-axis linkage function, can easily cope with these challenges and ensure processing accuracy and positional accuracy. Meanwhile, its rotary table can also conveniently achieve processing in the circumferential direction, such as various flange discs, gear discs, etc., improving processing efficiency.

Large and Heavy Parts

Horizontal machining centers are well-suited for processing large and heavy parts. Their robust construction and high load capacity make them ideal for handling components such as automotive engine blocks, industrial machinery frames, and large molds. These machines can accommodate workpieces of significant size and weight, reducing the need for multiple setups and ensuring consistent machining accuracy. By machining large parts in one operation, manufacturers can improve productivity and reduce production time.

High-Precision Parts

In industries where precision is paramount, such as the medical and electronics sectors, horizontal machining centers play a vital role. These machines are capable of achieving extremely high levels of accuracy, with tolerances often measured in microns. Medical implants, for example, require precise machining to ensure a perfect fit and functionality within the human body. Horizontal machining centers can produce these parts with the required precision, meeting the strict quality standards of the medical industry. Similarly, in the electronics industry, components such as circuit boards and connectors demand high precision machining to ensure reliable performance.

Multiple Operations in One Setup

Another advantage of horizontal machining centers is their ability to perform multiple machining operations in a single setup. This eliminates the need for transferring the workpiece between different machines, reducing setup time and minimizing the risk of errors. For instance, a part may require milling, drilling, tapping, and boring operations. With a HMC machine , all these operations can be carried out sequentially or simultaneously, depending on the complexity of the part. This not only improves productivity but also ensures better dimensional accuracy and surface finish.

Parts with High Volume Requirements

For manufacturers dealing with high-volume production runs, horizontal machining centers offer significant advantages. These machines are designed for efficient and continuous operation, capable of producing large quantities of parts with consistent quality. Automotive manufacturers, for example, rely on horizontal machining centers to produce engine components, transmission parts, and other high-volume parts. The ability to handle high production volumes makes horizontal machining centers a cost-effective solution for mass production.

Conclusion

HMC machine are capable of processing a wide range of parts, from complex geometric components to large and heavy workpieces, high-precision parts, and those requiring multiple operations. Their versatility, precision, and efficiency make them an essential tool in modern manufacturing. By understanding the capabilities of horizontal machining centers, manufacturers can optimize their production processes, improve quality, and increase productivity. Whether it’s in the aerospace, automotive, medical, or electronics industry, horizontal machining centers play a crucial role in shaping the future of manufacturing.