HM6380 Advanced Horizontal Machining Center for High Precision Industrial Machining

Horizontal Machining Center:

- The modified model is suitable for medium and small batches, and many varieties of box parts processing parts multi-sided drilling, boring, milling, tapping and other multi-process processing has the process content of completing the workpiece multi-sided in one clamping greatly reduce the number of processing procedures to improve processing efficiency and accuracy

share:

Beds

Inverted t-shape structure with large span overall bed design, large load bearing base, good rigidity;The base adopts the m-shaped bar network structure, with stable performance, rigidity and vibration resistance.The use of finite element analysis of static/dynamic Characteristics, uniform and reliable force, strong rigidity,Good vibration resistance.

Column

The column adopts the gantry frame structure design, which greatly enhances the torsional and bending resistance of the column.Built-in longitudinal and transverse ring reinforcements for uniformthermal deformation and rigidity.

FEA (Finite Element Analysis) is used to carry out static and dynamic characteristics analysis to ensure the best performance of the machine in dynamic and static conditions.

High rigidity

The machine is made of high grade cast iron and box structure design, properly annealed to eliminate internal stress, the material is tough, plus the box structure design, high rigidity body structure, so that the machine has sufficient rigidity and strength, the whole machine shows high cutting ability and high repeatability characteristics.

Control System

High-Performance Control System: Equipped with the FANUC Series Oi-MD, providing high precision, increased productivity, and enhanced safety in machining processes.

Expandable Memory: The control system supports CF card integration, allowing for increased external memory capacity.

Comprehensive Error Compensation: Various error compensation features enable high-precision machining, minimizing deviations and enhancing accuracy.

| ITEM | UNIT | PARAMETER(HM6380) | |

|---|---|---|---|

| Itinerary | Three-axis travel (X/Y/Z) | mm | 1000 ×800×850 |

| Spindle end face to table center (front and rear) | mm | 150-1100 | |

| Spindle center to table (top and bottom) | mm | 100-900 | |

| Maximum workpiece rotation diameter | mm | Ø1500 | |

| Workbench | Table area | mm | 630×800 |

| Maximum table load | kg | 3000 | |

| T-slot (slot × width × center distance) | mm | 5×18×120 | |

| Indexing angle | ° | 1 | |

| Spindle | Spindle type | mm | BT50(Ø190) |

| Spindle motor | kw | 15/18.5 | |

| Spindle speed | rpm | 6000 | |

| Tool Changer | Number of knives | T | 24/40 |

| Maximum tool diameter | mm | Ø112 | |

| Empty knife | mm | Ø200 | |

| Maximum tool length | mm | 400 | |

| Maximum tool weight | kg | 18 | |

| Tool change time (knife-to-knife) | sec | 3.5 | |

| Speed | Fast movement speed (X/Y/Z) | m/min | 20 |

| Cutting feed rate (X/Y/Z) | mm/min | 1-10000 | |

| Table rotational speed | rpm | 10 | |

| Accuracy | Positioning accuracy | mm | ±0.01 |

| Repeatability | mm | 0.01 | |

| Other | Total machine power supply capacity | kw | 50 |

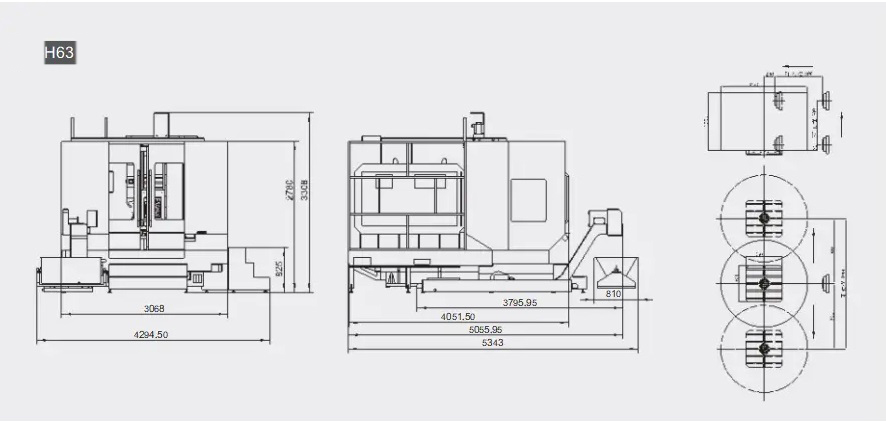

| Overall dimension | mm | 4000*3500*2600 | |

| Machine weight | kg | 15000 | |

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | FANUC | Japan | 0I-MF |

| 2 | Spindle Motor | FANUC | Japan | βiIP30/8000 |

| 3 | X/Y/Z/Fourth Axis | FANUC | Japan | βis30/2000 βiS40B/2000 βiS40/2000 βis22/3000 |

| 4 | Ball Screw (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 50/50/50 |

| 5 | Linear Guide (X/Y/Z Axis) | PMI/HIWIN | Taiwan | X45 /Y55/ Z55 |

| 6 | Screw Coupling | JANETECH | Taiwan | |

| 7 | Ball Screw Bearing | NACHI | Japan | |

| 8 | Motorized Lubrication System | HEGU | Joint Venture | |

| 9 | Spindle | POSA | Taiwan | |

| 10 | Tool Magazine | CHNCIT/OKADA | China | |

| 11 | Cooling Pump | STAIRS | Taiwan | |

| 12 | Pneumatic Components | SMC | Japan | |

| 13 | Transformer | LUHO | ||

| 14 | Electrical Components | SCHNEIDER | France | |

| 15 | Telescopic Cover | XM/ETEK | Taiwan | |

| 16 | Screw + Chain Plate Type Chip Conveyor | XM | ||

| 17 | Machine External Sheet Metal | XM | ||

| 18 | Fourth Axis | DETRON | Taiwan | |

| 19 | Hydraulic Station | 70CEAN | Taiwan |