NV1050 Precision Machining Centers For A Wide Range Of Industrial Applications

VMC Machining Centers Feature:

- High-speed, heavy-duty cutting, high-precision structural design;

- Short-nose spindle with high precision and rigidity;

- Spindle center air blast and air curtain protection;

- High-speed, high-precision performance control system;

- Fully enclosed protection.

share:

High-Performance Spindle

Spindle Center Air Blow: Keeps the tool holder clean, enhancing machining precision.

Spindle Air Curtain Protection: Prevents dust from entering the spindle bearings, extending spindle life.

Integrated Nozzles Around the Spindle: Eliminates the need for adjusting a single nozzle when machining complex shapes.

Guideways and Ball Screws

Three-Axis Guideways: Equipped with high-speed linear guideways from a renowned Taiwanese brand, offering high rigidity, high load capacity, high speed, and low thermal growth.

Three-Axis Ball Screws: Uses ultra-high-speed, ultra-quiet ball screws from a Taiwanese brand, featuring low noise, low thermal rise, high speed, and high rigidity.

Control System

Advanced Control System: Equipped with a high-performance, high-precision control system, the FANUC Series Oi-MD, enhancing accuracy, production efficiency, and process safety. The control system supports CF cards, allowing for increased external memory.

Comprehensive Error Compensation: The control system offers multiple error compensation features, achieving high-precision machining.

Oil-Water Separation Box

Oil-Water Separation Design: The machine tool is designed to separate oil and water, preventing 80% of dirty oil from mixing with coolant in the tank, thus maintaining machining quality.

Chip Conveyor

Chain-Type Chip Conveyor: The Chip Conveyor employs a chain-type chip conveyor. Chips and coolant flow down the steep protective cover to the side chip screws and are then expelled by the chain-type conveyor to the waste collection area, effectively reducing non-machining time and lowering labor intensity.

| Project | Unit | JN-NV1050 Belt type | JN-NV1050 Belt type | |

|---|---|---|---|---|

| Workbench | Table size | mm | 1300*550 | 1300*550 |

| T-slot | mm | 5*18*100 | 5*18*100 | |

| Table load | kg | 700 | 700 | |

| Travel | X/Y/Z travel | mm | 1050/550/600 | 1050/550/600 |

| Spindle nose to table surface | mm | 150-750 | 150-750 | |

| Spindle center to column surface | mm | 566 | 566 | |

| Spindle | Spindle drive method | Belt type/Direct type | Belt type/Gear type | |

| Spindle speed | rpm | 8000 /12000 | 6000 | |

| Spindle Motor | kw | 11-15 | 15-18.5 | |

| Feed Rate | X/Y/Z cutting feed | mm/min | 1~10000 | 1~10000 |

| X/Y/Z rapid feed | mm/min | 36000 | 36000 | |

| Accuracy | Positioning accuracy | mm | 0.008 | 0.008 |

| Repeat positioning accuracy | mm | 0.005 | 0.005 | |

| Automatic Tool Change System | Tool Magazine capacity | T | 24 | 24 |

| Tool change method | Disc arm type | Disc arm type | ||

| Max. tool diameter | mm | Φ85(Φ150 oval space) | Φ110(Φ120 oval space) | |

| Max. tool length | mm | 300 | 300 | |

| Max. tool weight | kg | 7(Tool deflection) | 8(Tool deflection) | |

| Spindle taper | BT40 | BT50 | ||

| Other | Power requirement | kva | 30 | 30 |

| Machine weight | kg | 7000 | 7000 | |

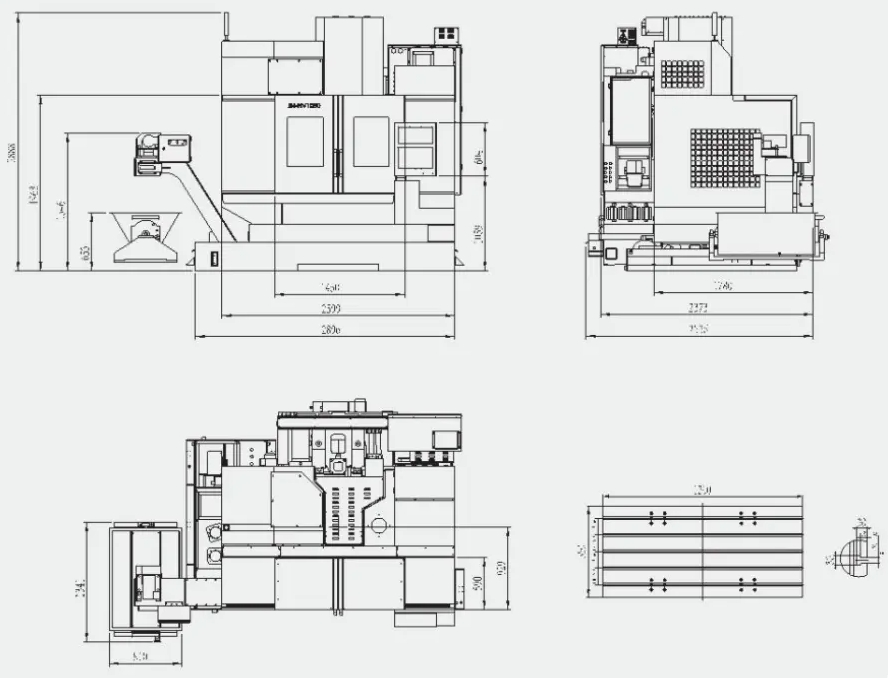

| Machine size | mm | 3670×2520×2870(including water tank) | 3670×2520×2870(including water tank) | |

| No. | Item | Brand | Brand Origin | Remarks |

|---|---|---|---|---|

| 1 | CNC Control System | FANUC | Japan | 0I-MF |

| 2 | Spindle Motor | FANUC | Japan | biI15/8000SP |

| 3 | X/Y/Z Axis | FANUC | Japan | ßis22/3000 ßis22/3000 ßis22B/3000 |

| 4 | Ball Screw (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 40/40/40 |

| 5 | Linear Guide (X/Y/Z Axis) | PMI/HIWIN | Taiwan | 45/45/45 |

| 6 | Screw Coupling | JANETECH | Taiwan | |

| 7 | Ball Screw Bearing | NACHI | Japan | |

| 8 | Lubrication System | HEGU | Joint Venture | |

| 9 | Boosting Cylinder | HINAKA | Taiwan | |

| 10 | Spindle | POSA | Taiwan | |

| 11 | Tool Magazine | CHNCIT | China | |

| 12 | Cooling Pump | STAIRS | Taiwan | |

| 13 | Air Tank | China | ||

| 14 | Pneumatic Components | SMC | Japan | |

| 15 | Transformer | LUHO | ||

| 16 | Electrical Components | SCHNEIDER | France | |

| 17 | Telescopic Cover | ETEK | Taiwan | |

| 18 | Chain Plate Type Chip Conveyor | XM | ||

| 19 | Machine External Sheet Metal | XM |

| Standard Configuration | Optional Configurations |

|---|---|

| Spindle center blowing | Control system (MISUBISHI M80A /FANUC Oi-MF PLUS) |

| Spindle air curtain protection | Inline spindle 12000RPM |

| Screw (Taiwan brand) | Oil mist recovery device |

| Guide rail (Taiwan brand) | Column heightening 150mm |

| Japanese NACHI bearing | Water gun |

| Fully enclosed protection | Fourth/fifth axis device |

| Pneumatic Components (Japan/Taiwan) | Automatic door |

| France SCHNEIDER electrical components | Center water discharge |

| Taiwan STAIRS cooling system | Tool setting instrument |

| Process blowing system | Hollow Screw |

| Joint venture HEGU lubrication system |